Categories

BPO-32 food grade

Categories:

Organic Peroxides

Email:icason@icason.com

Technical data sheet

Commodity Name: Diluted DiBenzoyl Peroxide 32% or benzoyl peroxide 32% or Flour Whitening Agent

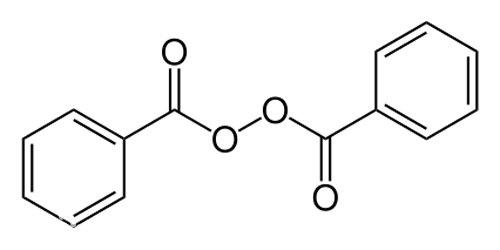

Molecular Formula: (C6H5CO)2O2

Molecular Weight: 242.2

Structural Formula:

Purity of Benzoyl Peroxide: 32%

Technology Index:

|

Appearance |

White and loose powder |

|

Content (B.P.O.) |

32% |

|

Moisture Content |

≤5.0% |

|

Fineness (after 200 mesh steel screen) |

≥90% |

|

Heavy Metal (counting with Pb) |

≤0.003% |

|

Arsenium(As) |

≤0.0003% |

Application:

It mainly used in whitening of wheat or corn powder.

Brief Description:

The product is dilution product of Benzoyl Peroxide, also called Flour Whitening Agent, It includes 32% of Benzoyl Peroxide and 68% of Starch,Phosphate is not easy to be fired.

Packing:

In export carton of 25kgs, net weight. This product should be handled with care when it is transported, sealed and stored in particular cool, dry and clean warehouse which is far from heat resource.

Details of Diluted benzoyl peroxide

1. effect of diluted benzoyl peroxide

main components

The main components of this product are mainly benzoyl peroxide ( bpo for short, phosphate and edible starch, etc. the product is a kind of colorless and tasteless white powder, and the content of its effective component (benzoyl peroxide) is (28-32) %.

After adding benzoyl peroxide to flour, it can react with water molecule in the flour and release active oxygen, which can not only oxidize polyene pigment, and whiten the flour, but also mature flour quickly. the main functions are as follows:

(1) maturing flour quickly

As the flour that milled newly is too viscid and lack of elasticity and toughness, it is not good to make flour products, especially to produce bread products. the surface of the products may be dark, which is difficult to leaven and is easy to shrink, and the structure is not even. the above shortcomings can be improved after the flour is stored for a period, which is called maturing of flour. for the flour without using diluted benzoyl peroxide, it needs over 20 days to finish maturing of flour by making use of oxygen in the air. the maturing of flour will be finished in 1~2 days if benzoyl peroxide is added to the flour. after the flour processing companies use the diluted benzoyl peroxide, the processed flour can be sold immediately, which can avoid mildewing of flour due to long-term storage.

(2) bleaching flour

The newly processed flour generally is yellow, which can be bleached after storing and making use of the oxygen in the air, but the effect is not good. after flour processed companies use diluted benzoyl peroxide, the flour can become white with the effect of benzoyl peroxide.

Besides, because the benzoyl peroxide is white powder, it is convenient to use and the effect of bleaching is good. so, at present many countries in the world generally use benzoyl peroxide to make maturing and bleach flour.

(3) improving flour extraction of wheat

The color of flour is one of the main indexes; people always think the whiter the flour, the better of the quality.

The flour color not only has something to do with technique and equipment, but also with flour extraction, generally speaking, the higher the flour extraction is, the worse the flour color is. some flour processing companies pay more attention to control flour extraction of wheat considering the flour color, while after using benzoyl peroxide, due to it can improve whiteness of flour, it can also improve flour extraction of wheat. several years the study result of honest company shows that adding benzoyl peroxide into flour can generally improve 4%~6% whiteness of flour and 2%~3% flour extraction, meanwhile, the color and luster of flour is still very good. so, after flour processing companies used benzoyl peroxide, due to the flour extraction of wheat is improved, which can bring good earnings to flour processing companies. besides, 2%~3% wheat output of a country will be relatively improved, so it has obvious social and economic benefits.

Features of diluted benzoyl peroxide

(1) stable products quality

The level of use of benzoyl peroxide in flour is little, and the influence on cost of flour is small, but the influence on the quality of flour is large. the chinese flour processing companies all know that the first consider is the quality of products when selecting benzoyl peroxide. the quality of haivli products is very stable, which is agreed by lots of flour processing companies for many years, so, there is no necessary to worry about the quality of flour due to additive when selecting honest products.

(2) rapid function speed of the products

The universal flour additive benzoyl peroxide function needs over 72 hours, while, honest flour additive benzoyl peroxide function only needs 30 hours to reach the optimum efficiency completely.

(3) bright, soft and natural flour color

After using products of other brands, the color of flour is improper white, the flour color is not bright; flour processing companies all know that after using honest flour additive benzoyl peroxide, the flour color is good, bright, soft and natural, so, the flour products are very welcome.

(4) good products free -running property

Due to the adding amount of benzoyl peroxide in flour is small, so the free-running property is very important. the products without good free-running property will appear material sticking and caulking, meanwhile, it is hard to mix evenly with flour, which will cause uneven color of the flour, influence heavily quality of flour, and result in heavy economic loss. the customers who have used honest benzoyl peroxide know that its free-running property is good and stable. it is unnecessary to worry about the free-running property of products when selecting honest products.

Key words:

Organic peroxides

Related Products

Online Message

* Note: Please be sure to fill in the information accurately and keep the communication unblocked, we will get in touch with you as soon as possible